RF SERIES PMSM INNER ROTOR HVLS FAN-THE MOST ENERGY-SAVING HVLS FAN

Once the concept of energy saving and environmental protection was put forward.Our RF series PMSM hvls fan came into beging. Except energy saving and low noisy ,the small and delicate PMSM motor makes our RF series PMSM hvls fan more light and fashion.

| Model | Fan diameter | Motor power | Max speed | Rated voltage | Air flow | Max coverage | Noise |

| HVLS-DP1573 | 7.3m (24') | 1.5KW | 57rpm | 220V/380V | 14800 m³/min | 1850m² | 43dBA |

| HVLS-DP1561 | 6.1m (20') | 1.5KW | 65rpm | 220V/380V | 13500 m³/min | 1480m² | 43dBA |

| HVLS-DP1555 | 5.5m (18') | 1.5KW | 75rpm | 220V/380V | 12000 m³/min | 1200m² | 43dBA |

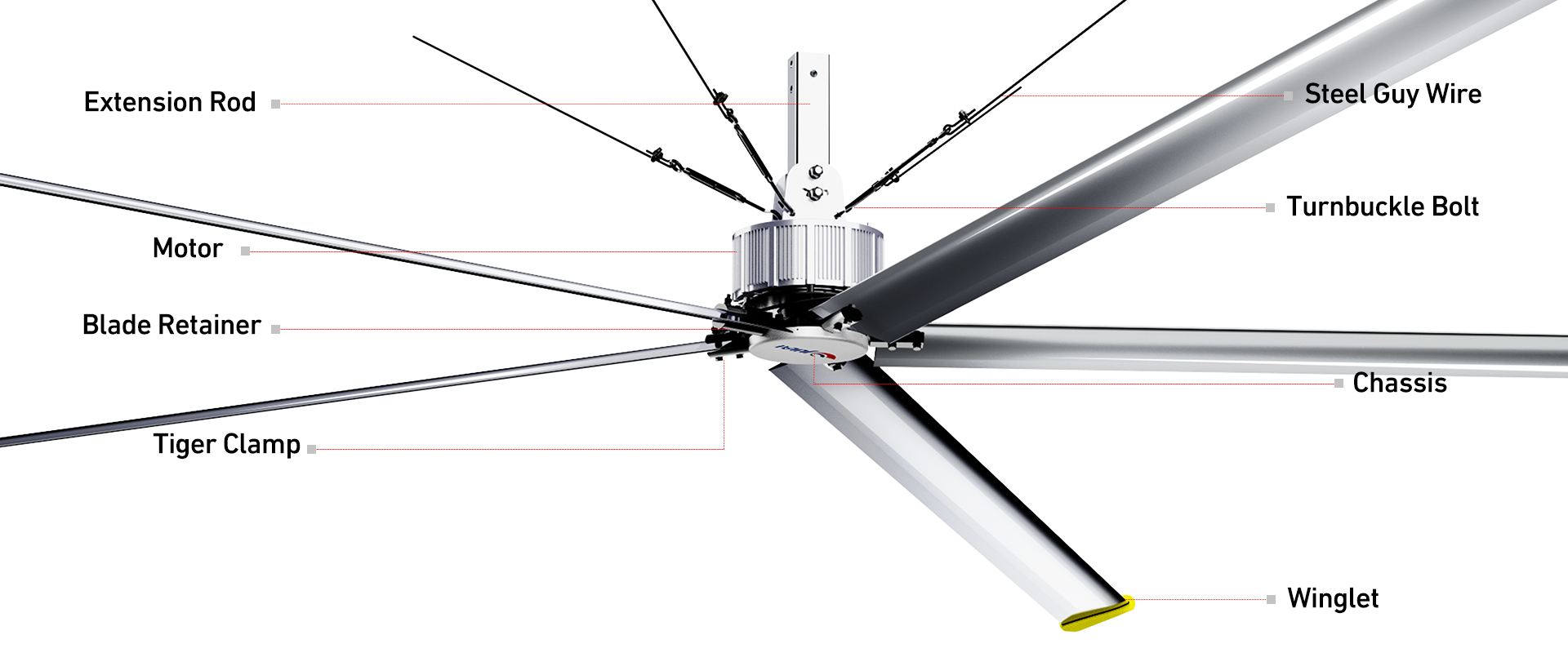

Our Advantage:

|

1.Fan Blades Made of aviation grade magnalium and finished in fluorocarbon coating to withstand the toughest environment. It’s unique patented design structure is further strengthened with 3 vertical stiffeners within the length of each blade to avoid structural fatigue. |

2.Winglet A winglet is attached to a distal end of the aerofoil to reduce drag and improve downward lift, creating up to 40% more air than most of our competitors. |

|

3.Blade Retainer Durable galvanized mild steel retainer link forms a unison binding strength to secure and lock all the blades to the hybrid hub strut. |

4.Steel Guy Wire 4 stabilizing guy wires for minimal lateral movement and vibration. Use turnbuckle to adjust the tension of each wire, ensuring that all cables are evenly stressed and the fan is safely and stably lifted. |

|

5.Tiger Clamp The enhanced plugin is the connector between the fan blade and the chassis, it is designed to hold 2 times more cross sectional area than most competitions. |

6.Chassis Made of Aluminium Alloy, our drive hub are made by 1500T hot press forging to ensure max mechanical efficiency. |

|

7.Control System Collaborating with world famous brands, our inverter offer top-class reliability and easy to use operation for peace of mind. |

Core Components:

|

1.Permanent Magnet Direct Drive Motor The PMSM adopts the principle of electromagnetic induction, double-bearing transmission, sealed structure, and military quality. It can realize motor maintenance-free, super quiet, and low energy consumption, as low as 0.3 kilowatt hours per hour. |

|

2.Fan Blades The fan blades are made of rust-resistant 6063T5 aviation magnesium-aluminum alloy material, which has enough toughness to ensure that it will not be brittle. The surface has been painted and has a corrosion resistance of more than 20 years. The fan blades have also been partially mechanically strengthened. , there are three reinforcing ribs, which greatly ensures the safety and strength. |

|

|

3.Control System: Our large industrial ceiling fans use "Danfoss" and "Hailip" transducer, the built-in RF interference filter, and the brake chopper has the function of restraining radio interference and braking,and has 12 major functions such as ground fault and over-short circuit protection.The box has a Schneider three-gear switch and an infinitely variable speed knob. |

|

4.Fan Hub As the main intermediate component that transmits power from the motor to the fan blades, we use 7075 grade aluminum alloy for high-pressure casting. The surface is sandblasted and then painted to slow down the impact of aging and the environment on this part, ensure the safety of the fan during use. |

|

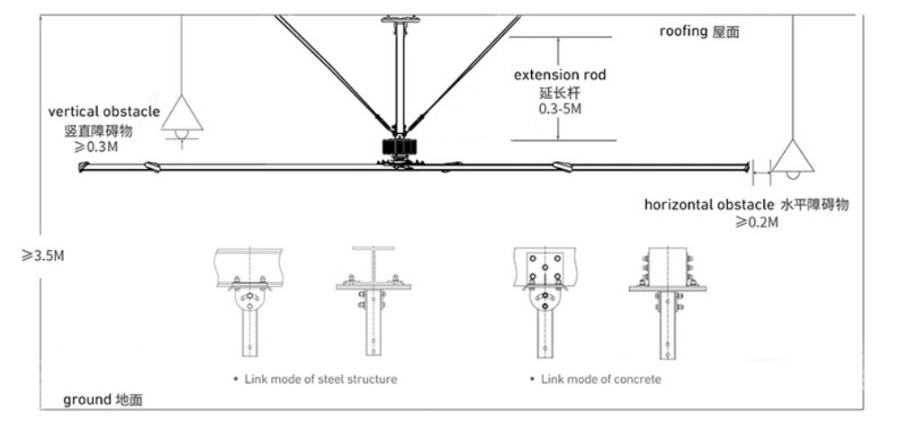

Installation diagram

|

● Tailor-made installation method; ● The installation process is concise and scientific; ● Building structure: H-shaped steel, I-beam, brick-concrete square beam, ball column structure, etc.; ● The safe distance between the fan blades and obstacles shall not be less than 0.3 meters; ● Input power supply can be 380V/220V. |

Our commitment to quality and durability:3 years

Warranty Period for all fan models begins thirty(30) days following shipment of the Product, Customer should retain necessary documentation to verify the date of receipt and installation of the Product. Customer will be required to produce this documentation in order to obtain Warranty services from JvlaiFans. This warranty covers any manufacturing defects that arise from normal usage within the warranty period. JvlaiFans will at its option and without charge, repair or replace the defective components or parts of the product on the condition that customer showing proof the items are within the warranty period.