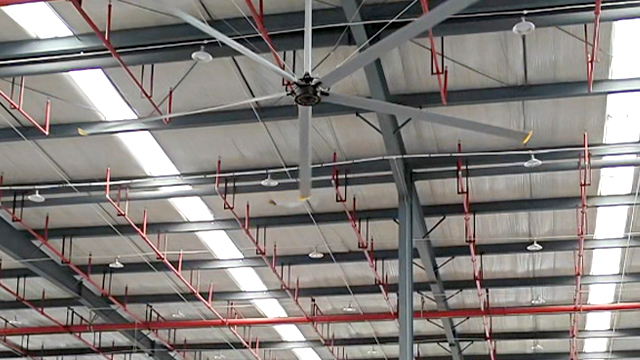

PMSM Ceiling Fans In Automobile Parts Warehouse

2025-09-12

|

Fans User:Parts Warehouse

Customer area:Chongqing, China

Application products:10 sets of 7.3m/24ft OF series industrial ceiling fan

Background

This warehouse is the storage center of an auto parts processing factory. It has a large area and a height of 8 meters per floor, but it doesn't have good natural ventilation conditions.

Dilemma

①. Fully enclosed warehouses lack natural ventilation conditions and rely on mechanical systems, but the exhaust ducts are prone to being blocked by goods;

②. Automobile components (such as rubber and plastic parts) release VOCs (volatile organic compounds), and continuous ventilation is required (recommendation: ≥ 6 times per hour); ③. The electronic components require a constant temperature and humidity (such as a temperature range of 20-25℃ and a humidity range of 40-60%). Poor ventilation can lead to oxidation or short circuits; ④. The warehouse has insufficient height (usually ≤ 8m), and high-density shelves (such as double-deep shelves) can block the airflow, creating ventilation dead zones.

Effect

● Industrial large fans can stir a large amount of air, creating a natural breeze effect, effectively improving the problem of heat in warehouses and reducing temperature stratification. Their coverage area can reach 800-1000 square meters. A single unit can meet the needs of large spaces. The energy consumption is only 1 kilowatt-hour per hour, with significant energy-saving effects;

● By enhancing air circulation, it can reduce ground condensation, keep the warehouse dry, prevent components from rusting or getting moldy, and is particularly suitable for the storage environment of humidity-sensitive automotive components; ● The application of permanent magnet synchronous motor technology has reduced energy consumption by more than 50%. Compared with traditional small fans or air conditioners, it can save up to 12,000 kilowatt-hours of electricity annually, and long-term use can significantly reduce operating costs;

● The lifting design does not occupy any floor space, avoiding interference with cargo handling and personnel operations. Multiple safety protection structures (such as fall prevention steel cables, overload protection) ensure the stable operation of the equipment.

|

|