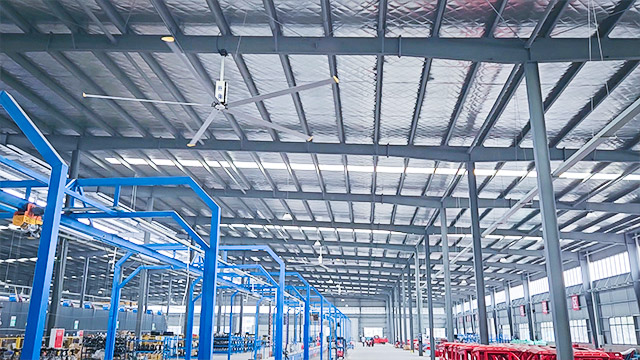

Big Ceiling Fans In Automobile Parts Factory

2022-10-07

|

Fans User:Automobile parts factory

Customer area:chongqing,china

Application products:20 sets of 7.3m/24ft OF series ceiling fans

Installation structure:I-beam structure

Background

The main business of the factory is the production and sales of motorcycle gears and automobile gears. It focuses on expanding the boundaries of gear manufacturing. Through horizontal integration, it has developed and manufactured various gear products that can be used in motorcycles, automobiles, wind power, mining, ships, high-speed rail and other fields. mass production capacity, and gradually developed into a comprehensive gear manufacturer. The company's total assets exceed 1.3 billion yuan, with an annual output value of 900 million yuan. Annual production capacity is 95 million pieces, with more than 2,000 categories.

Dilemma

①. Most auto parts are produced in large quantities. A single defect may cause batch scrapping or quality hazards. Some positions require employees to frequently move between several workstations. The parts produced are large and heavy, making employees' work complex and labor-intensive.The auto parts factory is a long-span steel structure factory. In summer, the factory is exposed to the scorching sun and internal heat accumulates. Employees rely on industrial horn fans to only provide air to a small area, and the cooling effect is not obvious. The fan blows directly onto the human body, making employees dizzy, lack of concentration may affect product quality;

②. The auto parts factory has a nut spot welding area. During welding, fine iron filings, particles, and dust will splash. A large amount of dust and iron filings float in the factory building. The air is turbid and the working environment for employees is poor. If it is not discharged in time, it will be inhaled into the body of employees,harm the health of employees. Effect

● Our engineers conducted on-site measurements and based on the actual conditions inside the factory, adopted a solution that combined fixed-point area air supply and special post cooling, and installed 20 sets of 7.3m/24ft energy-saving OF serise industrial fans in the factory;

● A row of large industrial fans is installed at certain intervals in areas with many equipment and parts stacked. Through the combination of multiple fans, the annular airflow formed by the fans is used to achieve fixed-point regional air supply.The natural breeze surges around the employees,can relieve employee fatigue,improve employee concentration; ● An energy-saving large fan is installed in the nut spot welding area. On the one hand, the operation of the propeller blades brings a large air volume of about 14800m3/min to blow the employees' bodies, dissipate the heat during welding and cool down the employees; on the other hand,the three-dimensional circulating air flow of the large fan continuously renews the indoor air, discharges dust and fine iron filings to the outside, and improves the air quality of the factory. |

|